Reduce Highway Skidding Incidents Through Friction-based Road Testing.

Continuous Road Testing offers technology that provides data on winter road conditions to municipalities and transportation infrastructure specialists. This data can be used to identify potential areas of danger on public roadways and provides immediate, actionable knowledge of winter driving conditions.

Through data-driven analysis of real driving conditions, our technology provides friction results that can help pinpoint areas that require changes to maintenance strategies and roadway engineering.

This technology can also be applied to fleets that may benefit from driver notifications of real time road conditions to inform road maintenance operations, or even commercial fleet applications.

Continuous Road Testing Limited

Friction lends to vehicles the ability to steer, brake or accelerate.

Friction lends to vehicles the ability to steer, brake or accelerate.

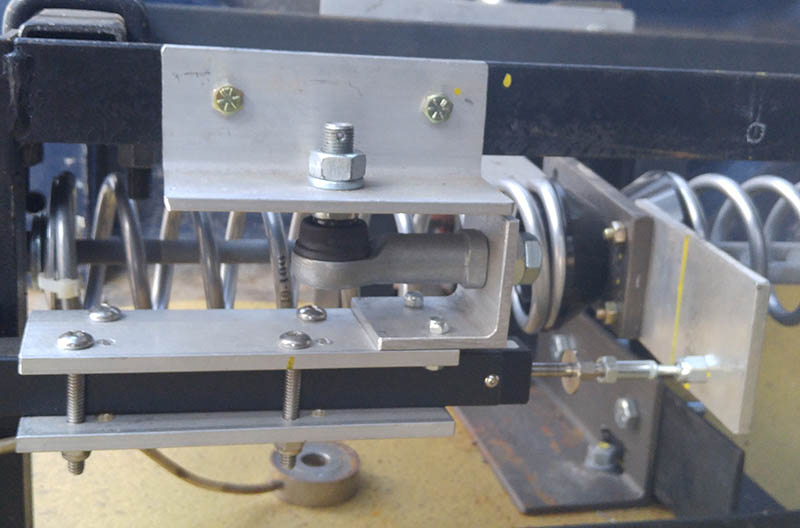

The Roadtester is a CFME, short for Continuous Friction Measuring Equipment. This CFME was designed for winter contaminant and therefore can reveal every small variation in available friction on the road surface in an accurate manner on a GPS-connected scrolling X-Y line graph. Our measurement of available friction is converted to a two decimal place number between .10 and .90 (coefficient of friction). We use a time-stable reference to keep measurements consistent. The testing can be performed without interruption for at least 800 kilometers so that a continuous data file can be recorded. For the most part the only maintenance required during the winter is changing tires and periodic calibration checks.

The Roadtester has introduced an innovation not seen on any other equipment – One test tire on the left side (wheel path or wheel track) and a second test tire on the right side. These two modules measure and record independently of each other so that irregular ice patterns on the highway are better defined. This is a “fail-safe” safety feature as well as contributing to hazard recognition capability. The earlier and more accurately that hazards are recognized the more time that the driver will be given to make a decision that could avert a skidding collision.

Get in touch for more information about the RoadTester system

Email:

leasing@roadtester.com

glenbrown@ice-check.com

Phone: +1-780-446-8044

Mailing address:

Continuous Road Testing Limited

Box 53600 Ellerslie P.O.

Edmonton Alberta T6X 0P6

Canada